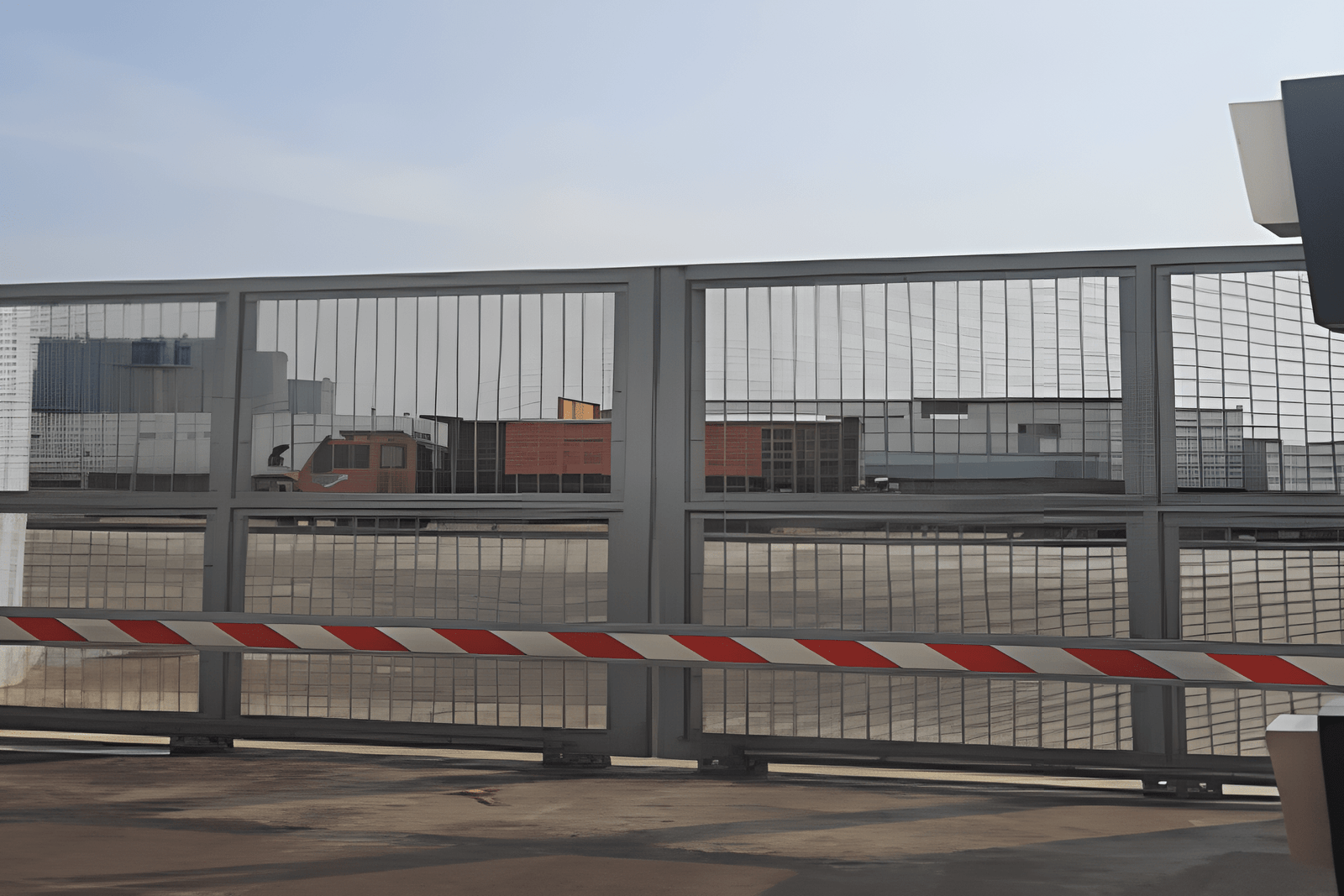

Anticlimb Fence

Dynoforce provides security fence solutions suitable to client requirements which can be as stated below

1.1

This specification defines the technical, material, structural, and installation requirements for the anti-climb fence system consisting of welded mesh panels, razor mesh topping, structural posts, cover plates, fixing hardware, and surface protection elements.

1.2

The fence system shall be designed to provide high-security perimeter protection, preventing climbing, cutting, tampering, and unauthorized access while maintaining a clean architectural appearance suited for critical infrastructure and sensitive facilities.

1.3

The scope includes the supply of all fence components, including posts, welded mesh panels, flat razor topping, cover plates, stiffening elements, and fixing hardware, along with complete installation on an existing concrete slab using base plate and anchor bolts.

1.4

The fence shall be compatible for use on standard perimeter slabs and shall also be suitable for integration with K4 crash-rated system, where required by the project. The security fence system with wall was tested at UK MIRA as per the latest test standards of ISO 22343-1:2023 Security Resilience - Vehicle Security Barriers.

1.5

Only fence systems that utilize the same construction methodology described in this specification — including welded mesh panel type, cover plate arrangement, post structure, razor topping, and fixing configuration — shall be considered acceptable for use.

2. System Description

2.1

The anti-climb fence (DF-SF-ACF) system shall consist of a high-security welded mesh panel assembly with a flat razor mesh topping, mounted on structural steel posts fixed to an existing concrete slab through base plates and anchor bolts.

2.2

Each fence panel shall be constructed using an anti-climb weldmesh with a nominal aperture of approximately 12.7 mm × 76.2 mm ± 3 mm, fabricated from high-tensile galvanized steel wires of approx. 4.0 mm ± 0.02 mm diameter. The mesh geometry shall prevent gripping, cutting, or foothold formation.

2.3

The fence shall incorporate a 500 mm high flat-type razor mesh topping, using CBT-65 blade profile and a galvanized high-tensile core wire. The razor topping shall be secured to the fence structure to prevent uplift, removal, or displacement.

2.4

Structural support shall be provided by SHS steel posts (approx. 80 × 80 × 4 mm) with welded base plates (approx. 200 × 200 × 10 mm), anchored to the existing slab using heavy-duty anchor bolts. Each post shall include a protective PVC top cap.

2.5

Each panel shall be supported and aesthetically finished using vertical and horizontal cover plates (flat bar type, steel), of specified thickness, installed to:

• Securely hold the panel in position,

• Provide a uniform finished appearance, and

• Add stiffness to the connection between the welded mesh and the razor topping.

2.6

Razor mesh, welded mesh, cover plates, posts, and structural stiffening members (including angle-type supports) shall function together as a single integrated fence assembly, ensuring stability and resistance to forced entry attempts.

2.7

All visible components shall be galvanized and polyester powder-coated in the RAL colour specified for the project. The system shall support a full range of RAL colours without modification to the structural configuration.

2.8

The fence panels shall be modular and designed for continuous installation along straight runs or corners, with consistent alignment, levelness, and panel-to-panel spacing in accordance with project requirements.

3. COMPONENT REQUIREMENTS

3.1

The fence panel ( DF-SF-ACF) shall be manufactured from high-tensile galvanized steel wires, approx. 4.0 mm ± 0.02 mm diameter, welded to form a mesh aperture of approx. 12.7 mm × 76.2 mm ± 0.3 mm.

3.2

The welded mesh shall have a nominal tensile strength in the range of 550–750 N/mm², ensuring rigidity and resistance to cutting or deformation.

3.3

The panel width shall be approx. 2450 mm, and the panel height shall be approx. 1500 mm. to 3000 MM Max.

3.4

All welds shall be consistent, clean, and free from sharp protrusions, ensuring safe installation and preventing tampering points.

3.5

A flat razor mesh topping of approx. 500 mm height shall be installed above the welded mesh panel to increase anti-climb protection.

3.6

The razor mesh shall use CBT-65 blade profile, manufactured from galvanized high-tensile core wire (approx. 2.5 mm core), providing aggressive anti-intrusion resistance.

3.7

The razor mesh shall be securely fixed to horizontal support members to prevent peeling, cutting, or bending during attempted breach.

3.8

Fence posts shall be fabricated from SHS steel, approx. 80 × 80 × 4 mm, with a minimum height of 1500 mm to 3000 MM Max support the panel + razor mesh assembly.

3.9

Each post shall be provided with a PVC cap for weather protection and to maintain a finished appearance.

4.0

All posts shall include a welded base plate of approx. 200 × 200 × 10 mm, designed for anchoring to an existing concrete slab.

4.1

The fence shall include vertical cover plates (steel flat-bar type) installed over the mesh/post junctions to secure the welded mesh panel, provide tamper resistance, and offer an aesthetically finished appearance.

4.2

Horizontal cover plates (steel flat-bar type) shall be used at the transition between the welded mesh and the razor mesh topping, providing structural stiffness and uniform alignment.

4.3

Only cover plate configurations that match the structural arrangement illustrated in the GA drawing (panel holding + razor mesh stiffness) shall be acceptable.

4.4

Cover plates shall be manufactured from structural steel and provided in a thickness suitable for panel rigidity and tamper resistance.

4.5

Angle-type supports (ISA-type structural angles) shall be provided at the top section to ensure proper stability of the razor mesh and resist deflection during external force attempts.

4.6

These stiffening angles shall function as rigidity enhancers and connection elements between posts and the razor mesh.

4.7

All fence components shall be installed using stainless steel (SS304) mushroom-head bolts with anti-tamper nuts.

4.8

Only tamper-resistant connection systems shall be acceptable for panel-to-post and panel-to-cover-plate fixings.

4.9

Self-tapping fasteners (stainless steel) may be used for securing horizontal or angle-type stiffeners, where applicable.

5.0

All fasteners shall be compatible with the coating system and shall not cause galvanic corrosion.

5.1

Each post shall be anchored to the existing slab using heavy-duty anchor bolts suitable for high-security perimeter fencing applications.

5.2

Anchor bolts shall meet minimum strength and embedment requirements appropriate for the load conditions and post configuration.

4. PERFORMANCE REQUIREMENTS

4.1

The fence ( DF-SF-ACF) shall be designed to prevent climbing by eliminating footholds and handgrip opportunities through a welded mesh aperture of approx. 12.7 mm × 76.2 mm, which shall not allow insertion of fingers or footwear.

4.2

The minimum combined height of 2275 mm (panel + razor mesh) shall provide a physical barrier adequate for high-security perimeter protection.

4.3

The 500 mm high flat razor mesh topping, using CBT-65 blades, shall significantly increase deterrence by preventing hand contact and upper-body leverage.

4.4

The welded mesh panel shall maintain rigidity under normal handling and environmental exposure without bending, warping, or detaching from the post.

4.5

Fence posts shall be capable of supporting the full height of the mesh and razor topping without noticeable deflection when subjected to typical perimeter fence loads.

4.6

Cover plates shall secure the mesh panel firmly in place and provide added stiffness to the assembly, preventing panel displacement or forced separation.

4.7

The fence system shall remain firmly anchored to the existing slab using base plates and heavy-duty anchor bolts, ensuring stability under operational conditions.

4.8

All structural components — mesh, razor topping, cover plates, posts, and stiffening angles — shall function as a unified system to maintain alignment and straightness across the fence line.

4.9

All accessible fasteners shall be tamper-resistant to prevent unauthorized removal or loosening of fence components.

5.0

The welded mesh shall be resistant to prying or leverage attempts, and joints secured using mushroom-head stainless steel fasteners shall inhibit tool access.

5.1

Fence panels shall be modular to allow installation on straight runs, corners, and elevation changes without altering the integrity of the fence system.

5.2

Panel joints shall align with posts and cover plates to maintain consistent spacing and rigidity throughout the installation.

5.3

Panels shall align vertically and horizontally with a consistent joint spacing throughout the fence line.

5.4

Posts shall be installed plumb within ±2 mm over the full height.

5.5

Panel positioning shall ensure uniform top and bottom offsets, maintaining alignment with adjacent fence sections.

5.6

The post base plate and anchoring configuration shall permit installation on K4 crash-rated system, enabling integration between crash-rated barriers and perimeter fencing.

5.7

No modification to the fence panel, post, or connection method shall be made during such integration unless reviewed and approved by the project consultant.

6 — FINISH & CORROSION PROTECTION

6.1

All fence ( DF-SF-ACF) components, including welded mesh panels, razor mesh topping, posts, vertical cover plates, horizontal cover plates, and stiffening angles, shall receive a corrosion-resistant finish suitable for long-term outdoor installation.

6.2

The finishing system shall ensure uniform appearance, durability, and protection against rust, abrasion, and environmental exposure.

6.3

All steel components shall be galvanized prior to powder coating to provide base-level corrosion protection.

6.4

Galvanizing shall cover all weld joints, structural edges, mesh wires, and hidden surfaces.

7.5

After galvanizing, all visible components shall be finished with a polyester powder coating, approx. 60 μm thick.

7.6

Colour shall be as per project-specified RAL code, and the system shall be capable of supporting any RAL colour without modification to the product’s structure.

7.7

The final coating shall be smooth, uniform, and free from defects including pinholes, drips, runs, blisters, cracking, or visible imperfections.

7.8

Edges of cover plates, posts, and razor support areas shall be properly coated to avoid premature corrosion.

7.9

All fasteners (mushroom-head bolts, anti-tamper nuts, self-tapping screws) shall be stainless steel to ensure compatibility with the powder-coated and galvanized steel members.

8.0

No fastener shall cause galvanic reaction or degrade coating performance.

8.1

Any scratches or coating damages occurring during transportation or installation shall be repaired using the manufacturer’s approved powder coat repair method or equivalent touch-up system.

8.2

Repaired areas shall maintain similar colour and corrosion resistance to the original coating.

8.3

The flat razor mesh shall be galvanized and powder-coated, providing protection for blade edges and the high-tensile core wire.

8.4

Coating shall not reduce blade effectiveness or interfere with the mechanical integrity of the razor strip.

Dynoforce provides fence solutions suitable to client requirements which can be Anticlimb ,358 and other variants